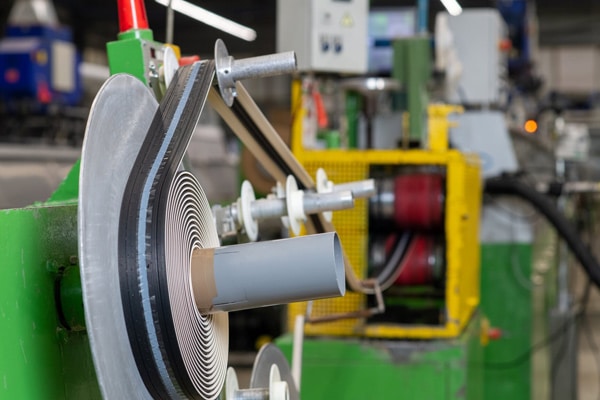

Co-extrusion

The TPP co-extrusion process makes it possible to manufacture profiles in 2 different colours or hardnesses.

As a result, the strong mechanical properties of the black EPDM rubber are combined with, for example, a colour coating on the visible side and/or another hardness which is more flexible. The advantage of this solution is that a good profile both aesthetically and functionally is manufactured. Time and costs are reduced by being able to save on post-processing and/or additional constructional elements.

Extrusion dies

Moulds are developed and manufactured in-house at TPP.

Co-engineering

The (co-)engineering of the right seal for customer specific applications.