Development and production of rubber sealing gaskets in many segments

Rubber sealing gaskets

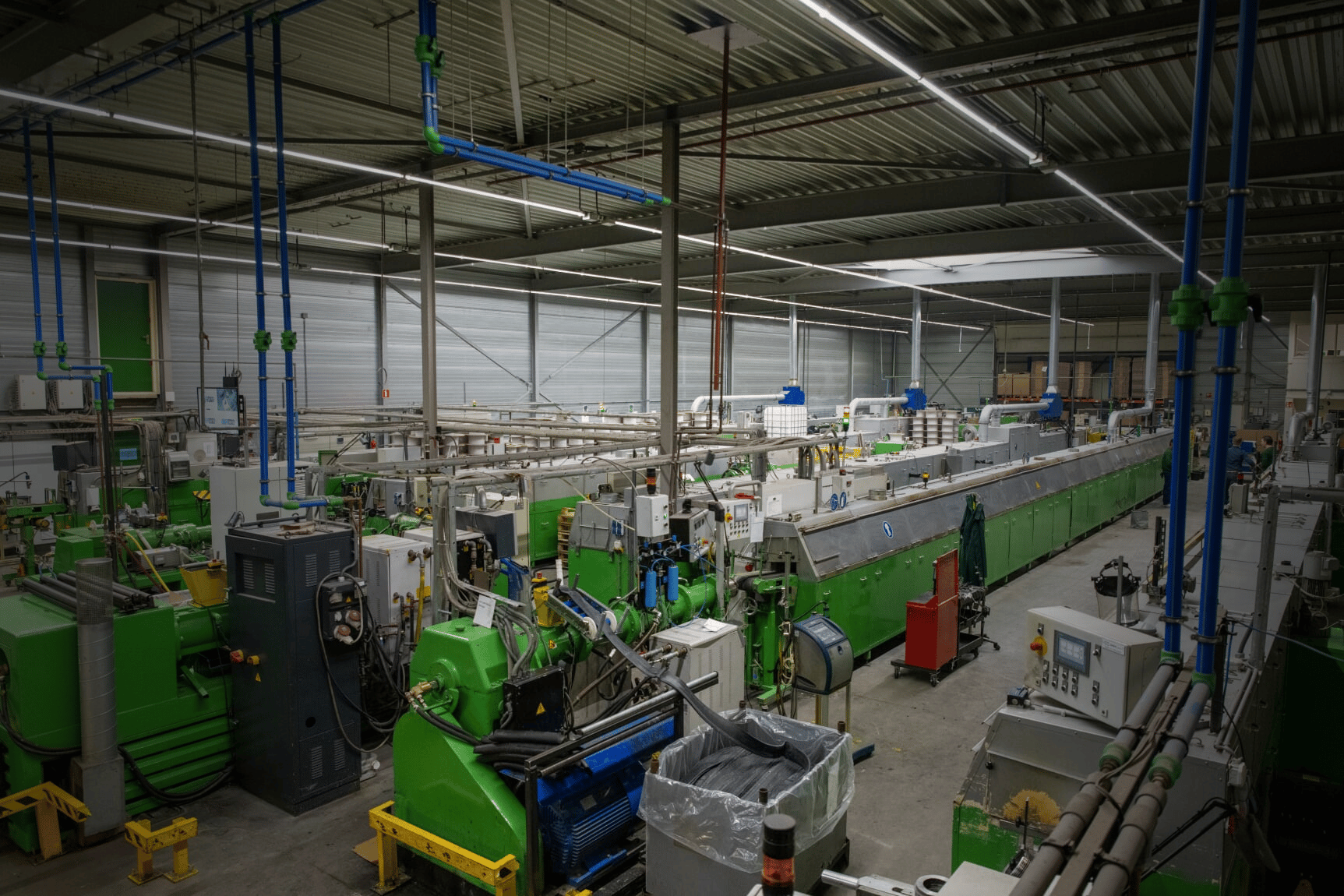

Since its foundation in 1999, TPP has been able to demonstrate its expertise in the development and production of rubber sealing gaskets in many segments and applications.

Wide range of rubber sealing gaskets

We see it as our mission to be the one-stop-shopping partner for our customers when it comes to the development and supply of flexible gaskets.

With a wide range of products, which consist of raw materials suitable for many applications, and by adding value to the end product, the total cost of ownership for you will be as low as possible.

We supply EPDM, TPE and silicone profiles in almost any required length, colour, and packaging. In the design we take into account the application, the specific ambient temperatures, indoor and outdoor use, insulation value, as well as the manual or fully automatic processing in the production process or on location.

Do you have a question about profiles?

Why rubber sealing gaskets?

Rubber, especially synthetic rubbers, has qualities that are extremely well suited for sealing or closing off elements. Rubber sealing gaskets are weatherproof, resistant to heat and cold, resistant to sunlight and dryness. Rubber sealing gaskets are robust, flexible, lightweight, can be easily compressed and return to their original shape (“rubber memory”), are damp-proof, airtight and keep out dirt and bacteria.

Rubber sealing gaskets are suitable for preventing leaks and pressure losses. Rubber profiles in the right design and made with the right compound are also suitable as insulators for heat, sound, or electricity.

Various applications for rubber profiles

Since its foundation in 1999, TPP has been able to demonstrate its expertise in the development and production of rubber sealing gaskets in many segments and applications. Our products are worldwide incorporated in many market segments and applications such as outer walls, window and door frames, horticultural greenhouses, conservatories, agricultural machinery, building elements, prefab houses, solar panels, packaging, industrial applications, offshore, marine etc. etc.

TPP rubber sealing gaskets are mainly used to flexibly seal a minimum of 2 elements and thus prevent leakage or pressure loss.

Various applications for rubber profiles

Since its foundation in 1999, TPP has been able to demonstrate its expertise in the development and production of rubber sealing gaskets in many segments and applications. Our products are worldwide incorporated in many market segments and applications such as outer walls, window and door frames, horticultural greenhouses, conservatories, agricultural machinery, building elements, prefab houses, solar panels, packaging, industrial applications, offshore, marine etc. etc.

TPP rubber sealing gaskets are mainly used to flexibly seal a minimum of 2 elements and thus prevent leakage or pressure loss.

Benefits of rubber sealing gaskets

- PRubber sealing gaskets contribute to a better living comfort and reduce energy costs by sealing different (inside and outside) areas.

- PRubber sealing gaskets prevent damage to joints of different elements by flexibly absorbing expansion and contraction.

- PRubber sealing gaskets help to prevent impact damage by e.g., shock, bounce, or impact force

- PRubber sealing gaskets are perfectly resistant to all types of weather, UV light and ozone. They are elastic and do not crack easily. In addition, they are highly resistant to wear and tear.

Rubber and durability with recyclable thermoplastics

It is our vision that the products we design, and supply will be manufactured in a sustainable way. We see the use of recyclable raw materials increasing in the future. We already offer the possibility of using recyclable thermoplastics in the development of new products or the so-called TPP-green compounds in which our vulcanised EPDM waste is processed as a vulcaniser. In this way, we try to fully process our residual materials into new end products.

Rubber and durability with recyclable thermoplastics

It is our vision that the products we design, and supply will be manufactured in a sustainable way. We see the use of recyclable raw materials increasing in the future. We already offer the possibility of using recyclable thermoplastics in the development of new products or the so-called TPP-green compounds in which our vulcanised EPDM waste is processed as a vulcaniser. In this way, we try to fully process our residual materials into new end products.

Questions

Leave your details and we will contact you as soon as possible.