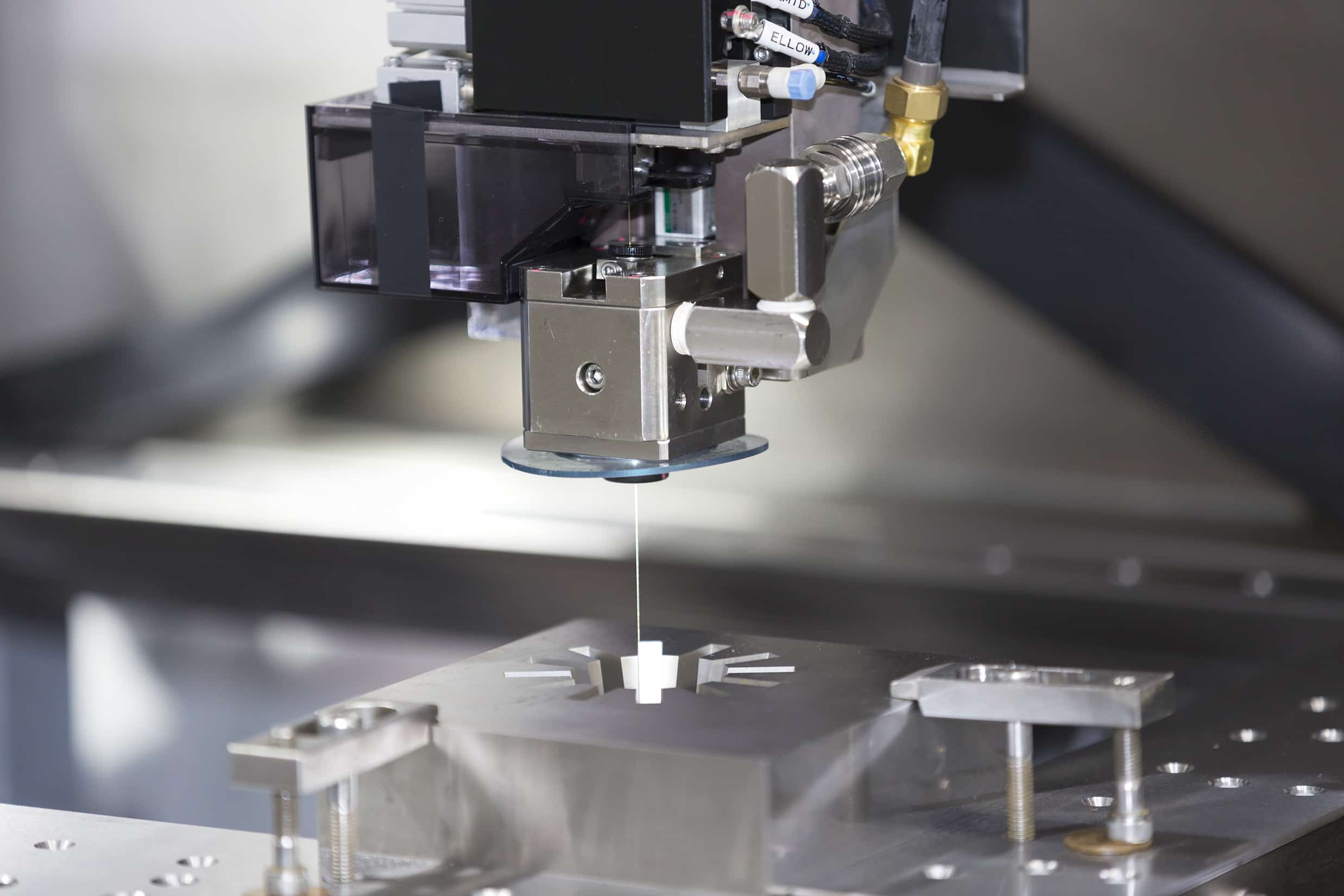

Extrusion dies

The development and production of the moulds we use in our production process is carried out entirely in-house by the professionals at TPP.

Many years of experience, combined with advanced software, electronic processing machines and craftsmanship, guarantee a solid mould. This mould forms the basis of the TPP production process. Developing completely in house means short circuits. In this way your specific wishes are streamlined and communicated to the departments Engineering, Mould-making and the Test sprayer. They then jointly manufacture the perfect design that exactly meets your expectations.

Experience, precision, quality and craftsmanship are the most important core values within TPP to realise the mould that serves as a basis for many metres of end product.

Distinctive techniques in which the professionals within TPP have specialised:

- development of dies for co-extrusion profiles

- development of moulds with a Butyl sealant coating in the profile

- development of moulds for profiles with hollow chamber

Extrusion

TPP is specialised in the extrusion of customer-

specific rubber sealing gaskets for various applications.

Co-engineering

The (co-)engineering of the right seal for customer specific applications.