Windows and doors

Project: The customer wanted this seal to be perfectly tight in the corners as well. Because of the specific shape (relatively large body with small lips), precise mitre cutting and gluing are almost impossible. We solved this by cutting the profile to a mitre in a special mould and then vulcanising it to a tight 90-degree angle by using film vulcanisation.

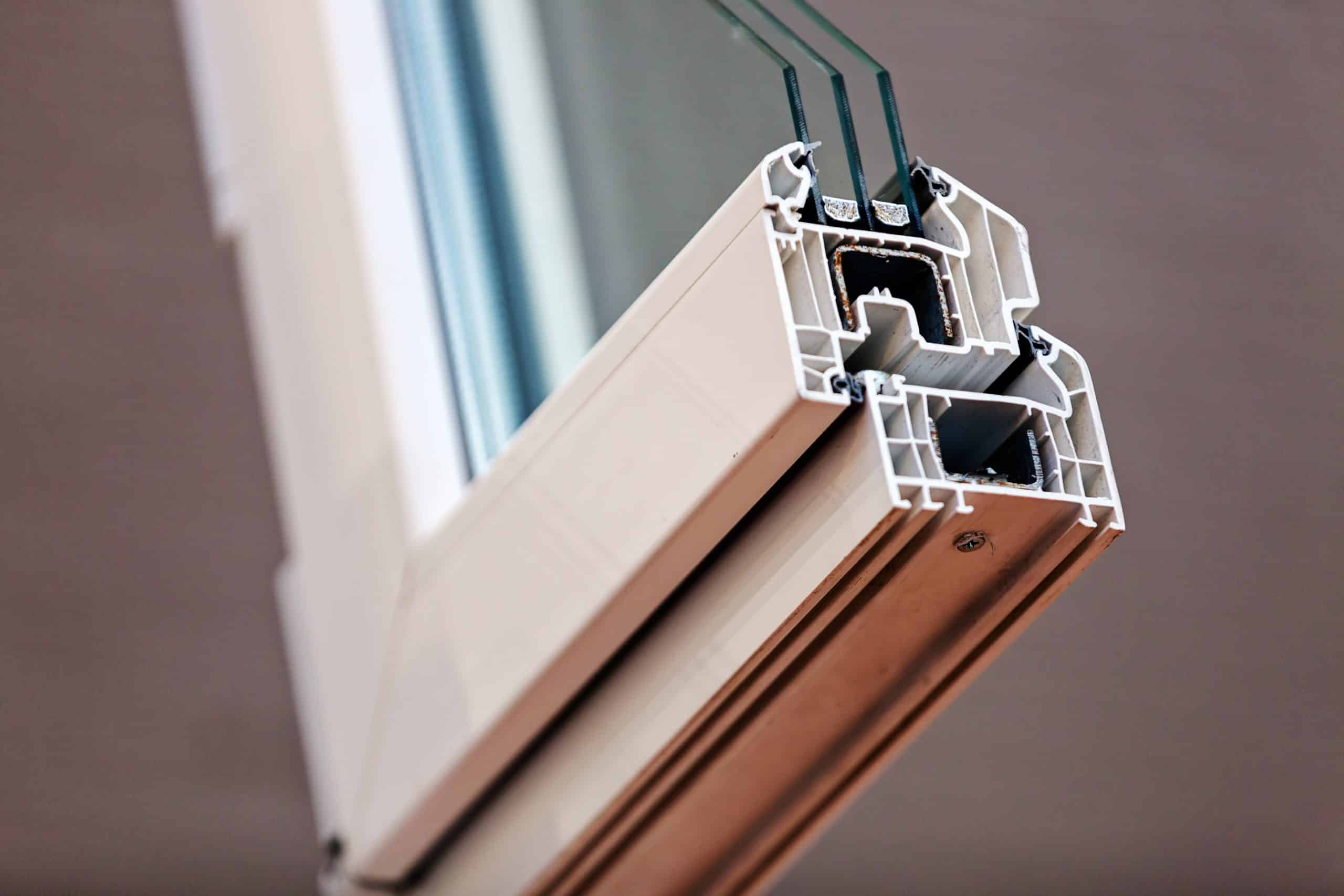

Project: The customer wanted to install rubber profiles in the window frames that do not stain. We were able to offer the solution of producing the profiles in TPE. Black TPE profiles are not staining, recyclable and easy to weld into windows.

Techniques used for this project

Extrusion

The extrusion of customer-specific rubber gaskets is our speciality! The application possibilities and specific ambient temperatures are endless for both indoor and outdoor use.

Corner vulcanisation

One of the TPP specialties is co-extrusion profiles. The TPP co-extrusion process makes it possible to manufacture profiles in 2 different colours or hardnesses.

Mould construction

The development and production of the moulds for the production process is carried out entirely in-house at TPP.